Powder Coating, Industrial Sandblasting and Cerakote

QUALITY SECOND TO NONE!

The best turnaround times in the business!

Operating from a convenient central location in North Okanagan, we are dedicated to delivering you high end specialty custom coatings.

We are equipped with a large curing oven (10ftx12ftx25ft) accomodating projects big and small.

The shop is outfitted with newly installed industrial sandblast booth (12ftx12ftx25ft) efficiently takling all of our customers blasting requirements.

*Image courtesy of Zeal Social Management

Services

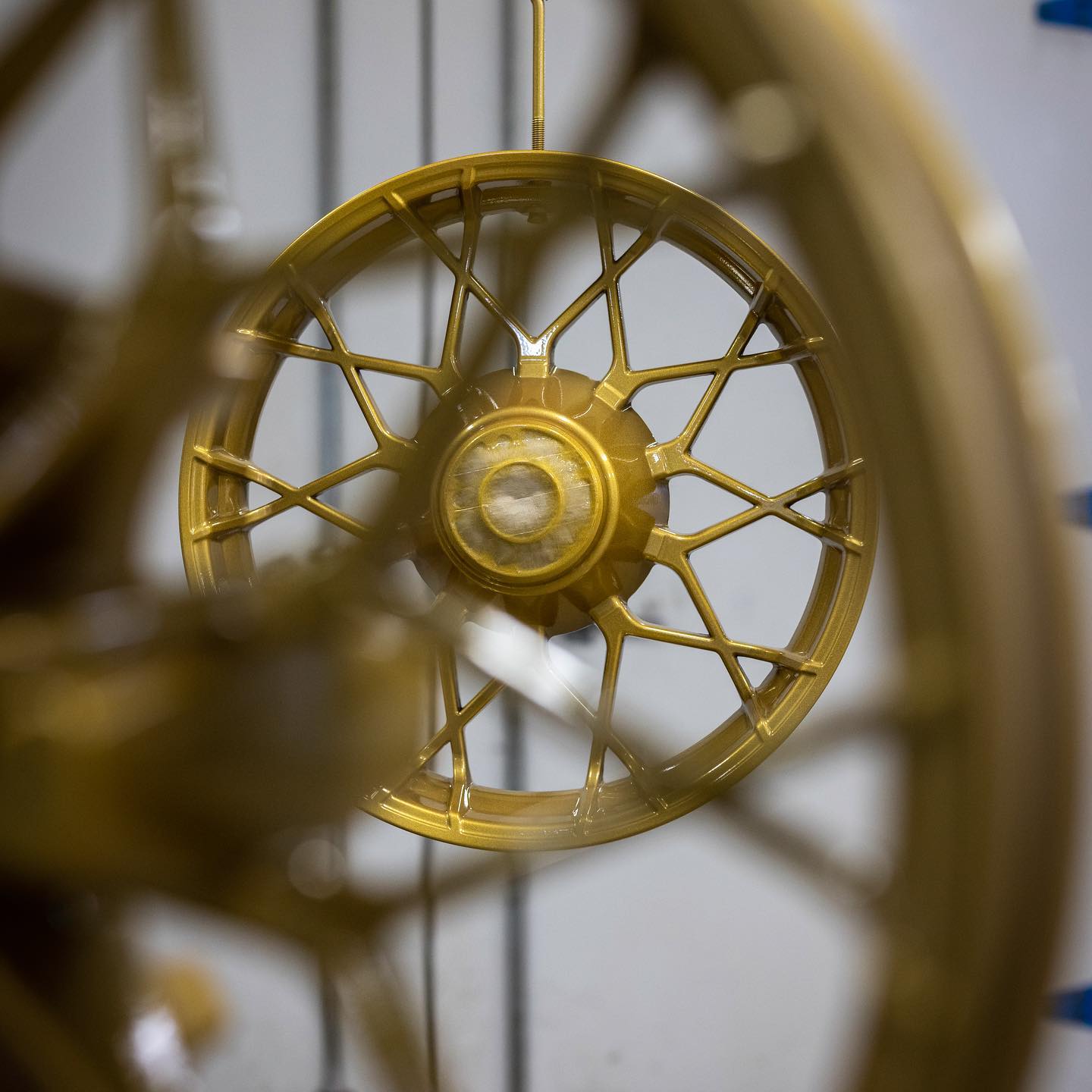

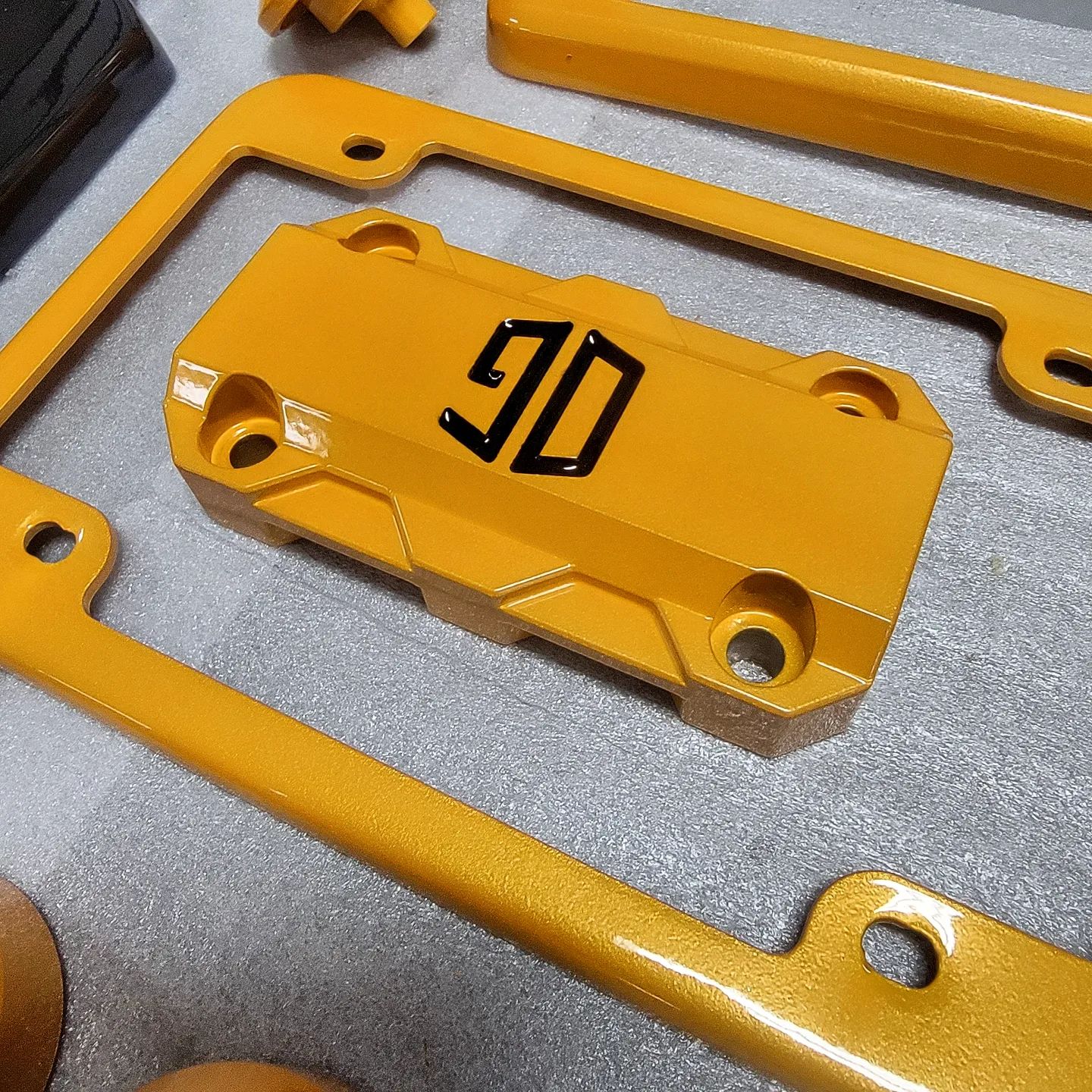

CUSTOM POWDER COATING

Our custom powder coating service utilizes advanced techniques to ensure precision and consistency, delivering high-quality results for a variety of applications. Whether you need to protect metal furniture, automotive parts, or industrial equipment, our professional team ensures a flawless and long lasting finish. With a wide rang of colors and finishes to choose from, you can customize your project to suit your style and preferences.

INDUSTRIAL POWDER COATING

When it comes to industrial powder coating, precision and quality are paramount. Our dedicated team utilizes advanced technology and rigorous quality control measures to deliver exceptional results. We carefully prepare the metal surface, ensuring it is clean and smooth, before applying the powder coating using precise equipment. You can trust us to provide a flawless finish that will protect and enhance the appearance of your industrial equipment, furniture, or components

SANDBLASTING

When it comes to removing tough coatings or preparing surfaces for painting and refinishing, industrial sandblasting is the go-to solution. This technique uses high-pressure sand or abrasive materials to blast away corrosion, rust, scale, and other unwanted residues from metal or concrete surfaces. It not only restores and rejuvenates worn-out surfaces but also helps improve the adhesion and performance of coatings. Industrial sandblasting is a cost-effective and efficient method that saves time and ensures long-lasting results.

Sandblasting: Aids in the process of adhesion by creating a profile to the metal surface. This process also ensures the surface results in a long lasting, smooth finish.

Application: Coating is applied using electrostaticity, which uses the combination of positive and negative ions which help adhere the powder onto the surface.

Curing: Heat cures the powder onto the surface forming a smooth, even and durable finish.

Protection: Additional coatings can be added at your request to further protect your metals.

Cooling: Once cooled, the powder forms a hard, protective layer and is ready for pick up!

Reviews

Did an amazing job in a very timely manner! Would definitely recommend to anyone needing a job well done

Antony did an amazing job on all my bike parts. Highly recommend this business!

Great Service, best quality for powder coating. always on time!

Get In Touch

- 4609 B 23 Street

- +1-250-545-4147

- protectallpowdercoating@gmail.com

- Monday to Friday 8:00 am - 4:30 pm